OVER 30 YEARS OF EXPERIENCE

about us

Complete Profiling Solutions Pty Ltd is a family owned an operated business located in Kings Park, Sydney. With over 30 years of experience in the steel industry, we have built our reputation with commitment, honesty and quality.

We have invested in the latest CNC machinery so we can deliver quality products and fast turn-around times to our customers. At our factory there are currently 3 state-of-the-art fiber laser cutting machines and 3 CNC hydraulic press brakes. This means there are several machines to ensure we can provide our customers with the most reliable, consistent service possible.

Here at Complete Profiling Solutions (CPS) our aim is to be dependable and efficient so that our work consistently meets your specifications, budgets and deadlines to ensure your projects stay on track. The team here are prepared to go the extra mile to ensure our valued customers are satisfied with our service.

wHAT wE dO

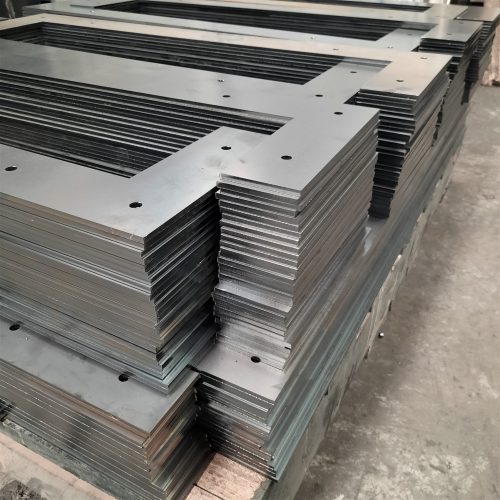

FLAT SHEET LASER CUTTING

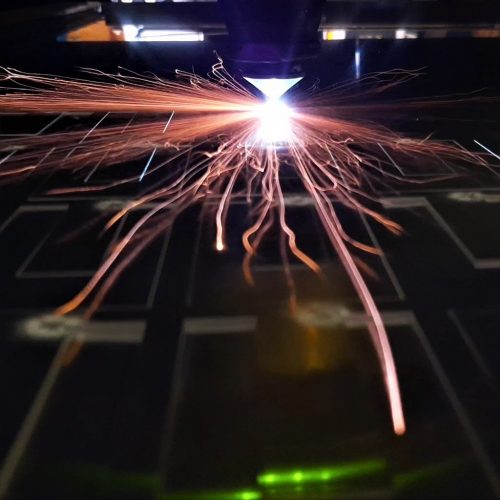

By using the latest state-of-the-art fiber laser cutting technology, we are able to offer a fast, precise and cost-effective solution for cutting a range of steels.

Maximum Sheet Size: 3000 x 1500mm

Mild Steel up to 25mm thick

Gal/Zinc Coated up to 3mm thick

Stainless Steel up to 16mm thick

Aluminium up to 10mm thick

We can also laser cut copper and brass.

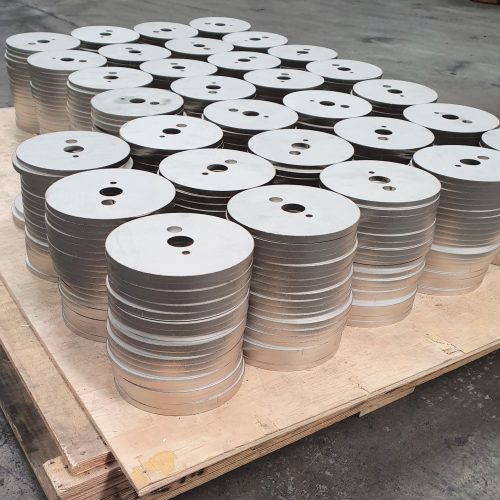

CNC BENDING

To maximise efficiency as well as save time and money for our customers, we have invested in three CNC hydraulic press brakes so that jobs can be laser cut and folded in the same place.

We specialise in batch and repetition production.

Maximum Length – 3000mm

Maximum Thickness – 20mm

Please feel free to give us a call on (02) 9912 5100 or email us at sales@completeprofiling.com.au with any questions about our capabilities. If you have any drawings or sketches for your job please send them through as this will greatly help our team assist you with your enquiry.

INDUSTRIES WE SERVE

CONSTRUCTION

STEEL FABRICATION

MINING

ENGINEERING

TRANSPORT

HOSPITALITY

DEFENCE

AGRICULTURE

HEALTH

FAQS

What is laser cutting?

At Complete Profiling Solutions (CPS) we use the latest fiber laser cutting technology. Putting it simply, the process of laser cutting involves a laser beam that is created by the laser source, which is then focused through a lens at a very high power on a very small point. The energy produced by this is converted into heat, which melts the steel plate. The benefits of fiber laser cutting include time and cost efficiency, great accuracy and precise, clean cuts.

What can we cut?

We can cut any 2D shape from metals such as mild steel, stainless steel, aluminium, brass or copper. We only offer flat sheet cutting, we do not cut 3D materials such as tube/pipe or any other pre-formed shapes. We also do not cut any materials other than steel, so we do not cut things like acrylics/perspex, fabrics or wood.

Can I use my own material?

We prefer to not cut our customer’s materials as there is always the risk that the cutting process may not run as smoothly as planned and if something goes wrong, we may possibly need to re-cut the job. The steel also has to be completely flat with no rust, coatings (apart from PVC) or damage on the surface in order for us to be able to cut it. If you do have your own material that you would like to use, please contact us and we will try to help the best we can.

Will I need a drawing for the items I need made?

We can use any form of drawing; if you do not have CAD drawings, our in-house CAD drafting department will help you develop what you need. For jobs with a large variety of plates or with an intricate design, we would prefer to use the customer’s CAD files, either in the format of .DXF or .DWG.

How long will it take?

We offer a standard lead time of around 3-5 days, depending on the number of plates and thicknesses/materials required. We are able to provide a same or next day turn around for any urgent jobs, to ensure you are able to stay on schedule (this also depends on the number of items/materials required. We can also offer delivery services, so please contact us with your requirements.